UV-Curable Glass Ink and Its Inkjet Printing Application

Abstract:

UV-curable glass ink, with its advantages of energy conservation, environmental protection, high efficiency and digital printing, especially when combined with UV-LED technology in inkjet printing processes, demonstrates significant application potential. In addition, this paper elaborates on the formulation design of UV glass ink, providing theoretical guidance and technical references for the research and development as well as industrial application of UV glass ink.

The main component of glass and ceramic inks is silicate. These materials are hard and brittle, with certain polarity on their surfaces, so they have lower requirements for ink flexibility. However, due to the dense structure of glass, UV inks cannot achieve adhesion through penetration, resulting in insufficient bonding force with the substrate. To solve this problem, the adhesion performance of the ink can be significantly improved by adding silane coupling agent KH570.

I. Classification of Glass Inks

✿ 1.Solvent-based one-component low-temperature baking ink

✿ 2. Water-based low-temperature baking ink

✿ 3. Two-component self-drying ink

✿ 4. High-temperature sintering (tempering) ink

✿ 5. UV-curable ink

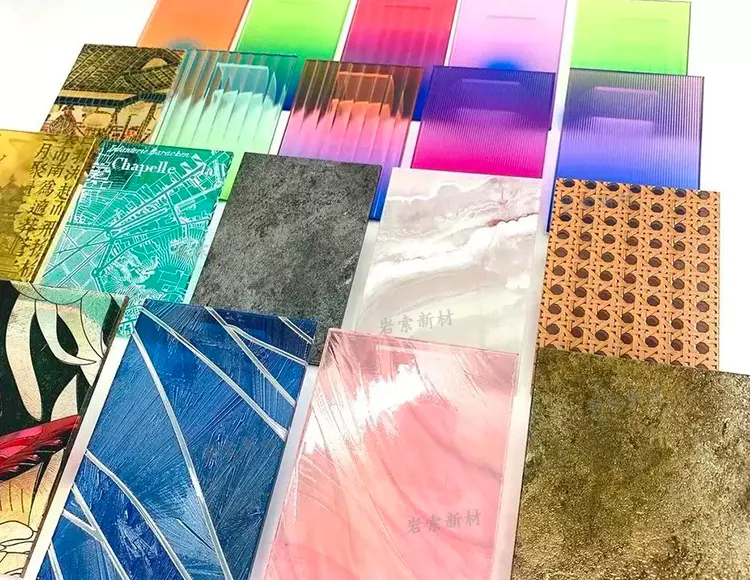

UV-curable glass inks stand out due to their advantages such as energy conservation, environmental protection, efficient curing, and convenient operation. Especially when combined with inkjet printing technology, UV inks enable digital and personalized printing without the need for plate-making. If UV-LED curing technology is further adopted, their environmental friendliness and cost-effectiveness will become more competitive, thus gaining wide recognition in the industry.

II. Advantages of Inkjet Printing in Glass Printing

| Low Cost | Plate-free printing, reduced number of staff, fewer production processes, simple proofing, and small space requirement. |

| Environmental Friendliness | No VOCs (Volatile Organic Compounds) and no residual harmful substances on printed products. |

| High Production Efficiency | Eliminates processes such as plate making, proofing, and ink drying, enabling instant printing and retrieval. |

| Wide Range of Substrates | UV inks are not limited by substrate materials; the printing width can reach 2.5 meters and the thickness up to 200 millimeters. |

| No Registration Deviation | No need for color registration printing; color printed products can be completed in one go. |

| High Flexibility | No minimum order quantity requirement; real-time correction of original content is possible; the size, material, and binding method of substrates can be changed at any time. |

| Printing on Glass | High reproduction accuracy of the original, printed products have good adhesion, and possess properties such as wear resistance, corrosion resistance, weather resistance, and light resistance. The use of white ink can easily change the light transmittance of glass, and even achieve ultra-fine frosted effects. |

| Wide Color Gamut and Consistent Color | 7-color printing (CMYK + LC/LM + W, i.e., Cyan, Magenta, Yellow, Key/Black + Light Cyan/Light Magenta + White); UV inks contain no solvents, resulting in more vivid colors. |

III. Key Points for Formulation Design of UV Glass Ink

✿ 1. Reactive Diluent:

Monomers with low surface tension (< 28 dyn/cm) such as TMPTA、TPGDA、IBOA and HEMA are preferred to enhance wettability on the glass surface;

✿ 2. Photoinitiator System

A combination of photoinitiator ITX, 907 and TPO is used, which matches the 320-380nm ultraviolet light source;

✿ 3. Oligomer Selection:

Silicone-modified acrylic resin has dual functions — silane groups condense with the glass substrate, and acrylate groups participate in photocrosslinking;

✿ 4. Pigment Requirements:

It must withstand heat treatment at 200℃ for 60 minutes, and have migration resistance and weather resistance properties;

✿ 5. Adhesion Enhancement:

Adding 0.5%-1% KH570 coupling agent can increase adhesion by 300%, and trifunctional ester can synergistically enhance the interfacial bonding strength.

If you have any product requirements or technical inquiries, please feel free to contact us at any time. We look forward to cooperating with you!